Frequently asked questions about photovoltaic constructions

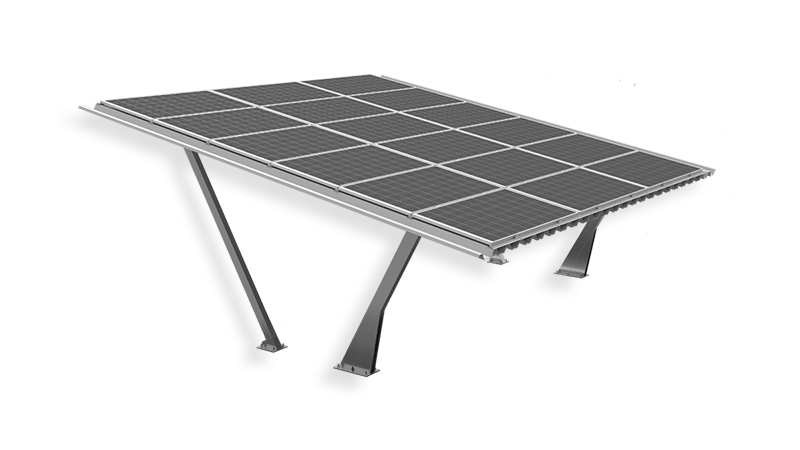

What profiles for photovoltaic modules?

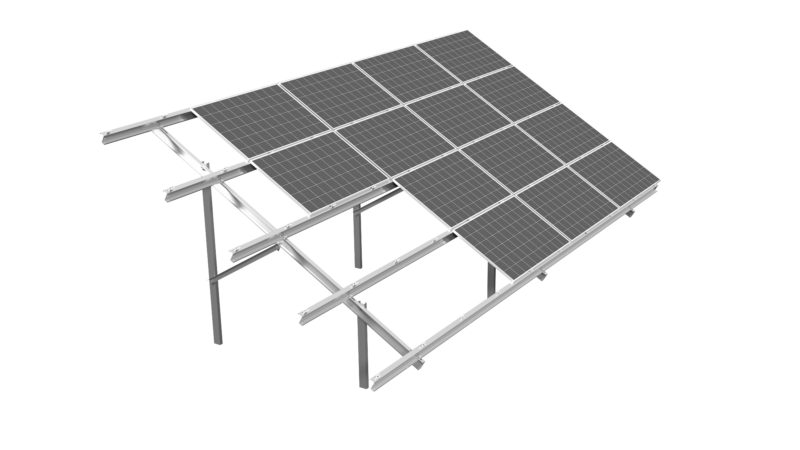

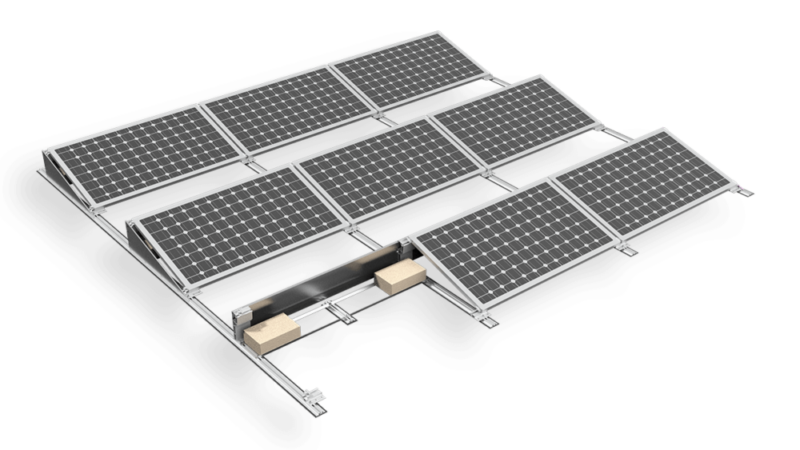

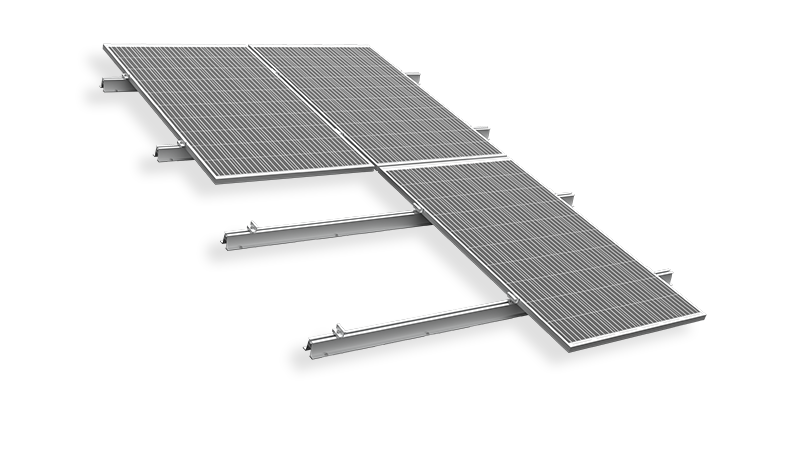

The selection of mounting profiles depends primarily on the type of PV structure. We will use different profiles when building a ground system, and different profiles for building a pitched or flat roof system. We offer several dozen system solutions, selected according to the individual needs of the customer.

What are photovoltaic structures made of?

Profiles for free-standing structures are made of high-quality black steel, which is reinforced with a layer of the innovative Magnelis® metallic coating. This is related to our mission, which assumes providing the market with extremely corrosion-resistant solutions, showing durability even in aggressive environmental conditions with a corrosion class of C5.

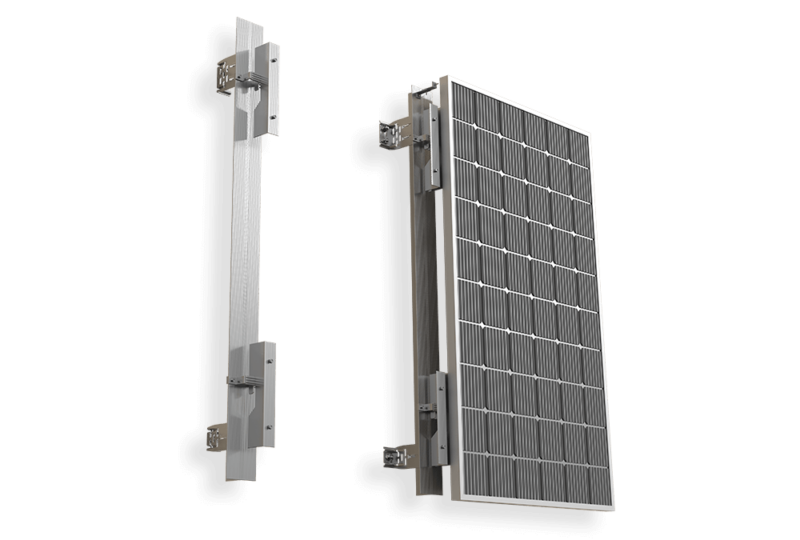

Roof structures and those intended for installation on building facades are made of the best quality aluminum. The key when installing this type of structure is the weight of the elements, which must guarantee not overloading the roof or facade surface.

How are the modules attached to the PV structure?

The photovoltaic module is attached to a steel or aluminum structure with a mounting clamp. Its size depends on the thickness of the module frame – this is the information that we require each time when placing an order. Importantly, at the customer’s request, we can order the clamps to be painted black so that they perfectly match the black surface of the PV panels.

What is the National Technical Assessment issued for Energy5 by the Building Research Institute?

This is the so-called a reference document that allows the construction product to be placed on the market and to be used in construction on the domestic market.

Recipients of our constructions gain the best safety guarantee on the market and confirmation of the widest range of technical features, going beyond the features declared on the basis of the PN-EN 1090-1 standard.

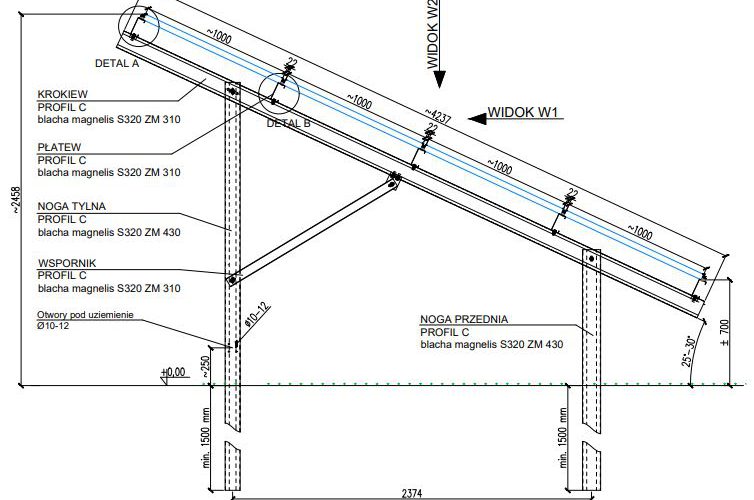

What steel is best to create a ground PV structures?

In Energy5, we use black steel S320-S450, covered with an innovative anti-corrosion coating Magnelis® ZM 310, ZM 430 or ZM620. Its above-average strength gives us confidence that it can be operated without failure for many years. The durability of the steel has been tested during tests in salt chambers, which confirmed its anti-corrosion resistance to the environment of the C5 corrosion class.

How are photovoltaic systems designed?

We treat our products as sets – the jointly tested parts are a guarantee for our customers that the system will be safe to use regardless of the wind and snow zones in force in a given location. We treat each project individually – regardless of whether it is a home installation or a large-area PV farm. We use the technologically advanced AutoCAD software and the support of qualified engineers who, when designing, take into account land development plans, the type of PV modules selected by the Investor, as well as the specificity of the location provided for the construction of PV.

To what depth are the profiles of free-standing PV structures driven?

The depth of foundation of above-ground structures depends primarily on the type of ground intended for the installation of the photovoltaic system. For household structures, the standard depth is 1.5 meters for two-support structures and 2 meters for single-support systems. It is important that during the implementation of large projects, we recommend performing vertical pull-out tests for structural piles that we have in our offer. The points selected for testing allow you to determine the condition of the ground and are a perfect complement to the geotechnical tests and other documentation provided by the customer.