What affects the lifetime of photovoltaic structures?

By investing funds in photovoltaic installations, we want them to be as durable and resistant to weather conditions as possible. We also consider effective, long-term and uninterrupted production of electricity to be extremely important. As a manufacturer of mounting systems for PV modules, we suggest what, in the case of supporting structures, has a positive effect on their durability.

1. In-depth analysis of ground and weather conditions.

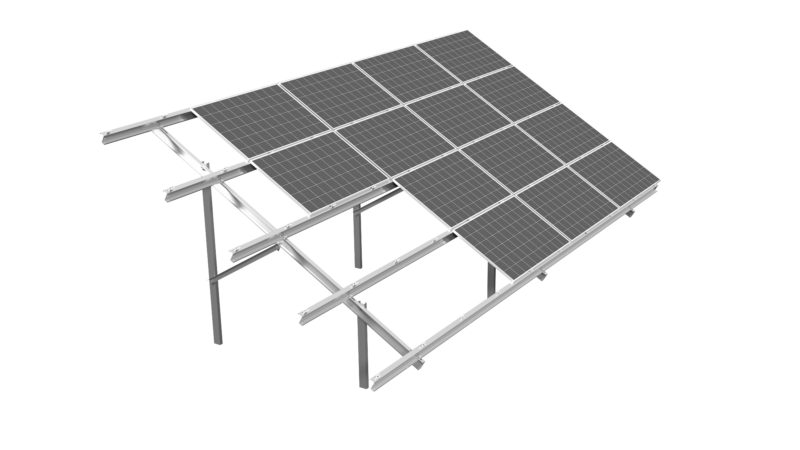

In order to maintain its stability, the photovoltaic structure should each time be adapted to the geological conditions found on the investment site. The documentation provided by the customer helps the Energy5 designers to assess the quality of the soil, thanks to which the engineers can determine the depth of driving the construction piles. The length of the profiles piled into the ground also depends on the wind and snow zone in the location intended for the construction of the PV installation. Subordinating the project to such requirements is a guarantee of safe use of the set of products.

2. Individually designed mounting system.

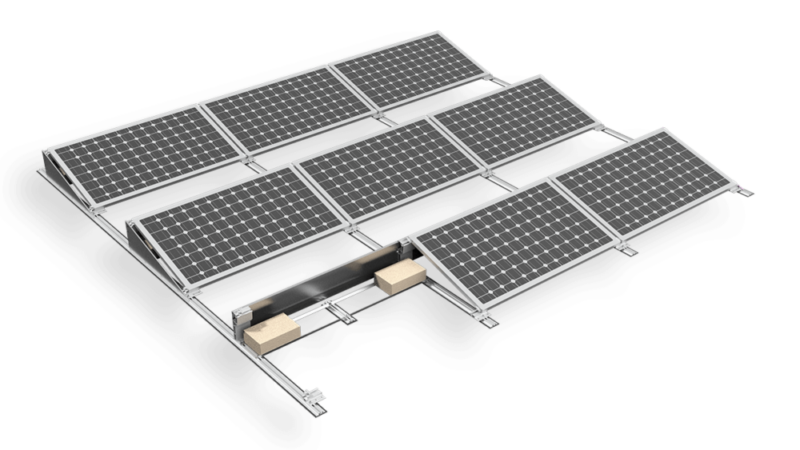

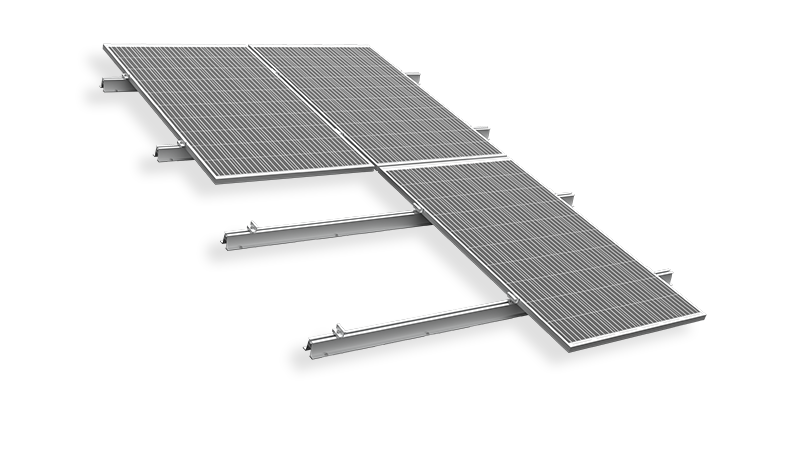

The photovoltaic structure itself, in addition to external conditions, should also be adapted to the type of modules selected for a given investment. The perfect selection of mounting elements means that the panels will be fixed in a way that does not allow them to move. At Energy5, we make sure that each order is treated individually and meets the customer’s requirements. The guidelines of the module manufacturers regarding their proper mounting in the PV installation are also important to us.

3. Production of components from the highest quality raw materials.

The base materials from which all types of construction products are made determine their actual technical characteristics. The anti-corrosiveness of the structure has a fundamental importance in the photovoltaic industry, which allows you to locate them literally on any surface, regardless of the corrosion class of the environment. Steel with Magnelis® coating used in Energy5 means that our solutions can be installed even in coastal areas with high salinity (corrosion class C5).

4. A safe process of loading, transporting and unloading assembly structures.

A properly planned and controlled logistics process is something worth paying special attention to when implementing a photovoltaic investment. Taking care of such issues prevents damage to structural elements, e.g. dents and undesirable scratches of the steel coating, which may weaken its anti-corrosion properties.

5. Correct installation of the photovoltaic support system.

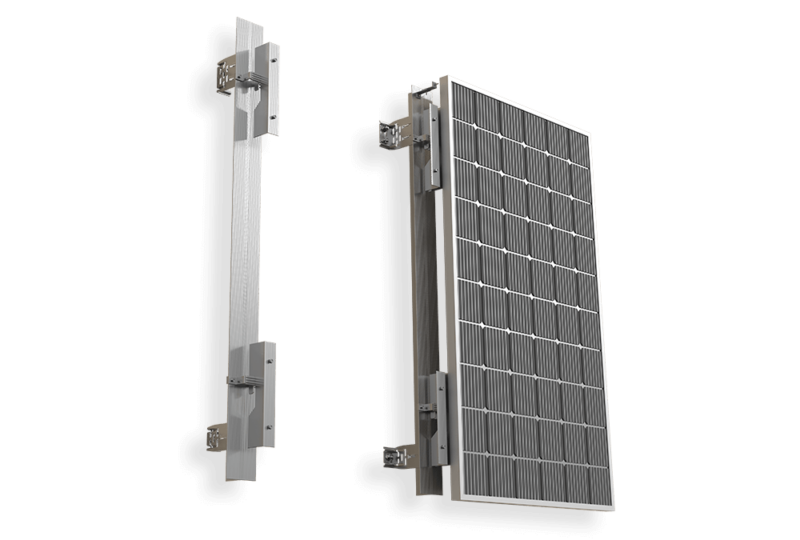

In the assembly of each PV installation, not only the profiles count, but also literally every clamp, screw and washer. Proper fitting of all system components is a condition for meeting the warranty provisions and ensuring the subsequent safe operation of the photovoltaic structure. For its correct screwing, we recommend using high-quality torque wrenches or using the service of comprehensive installation of PV systems by the Energy5 team – from piling to laying the panels on the structure.

6. Care for the structure during the period of use.

If you want to enjoy the excellent technical properties of the photovoltaic support system for a long time, follow the provisions contained in the technical and operational declaration. In it you will find e.g. instructions on how to store, install, clean or maintain the PV structure. It is also worth emphasizing the essence of the conditions used in the production of steel with the Magnelis® coating, the observance of which will extend the durability of free-standing installations.

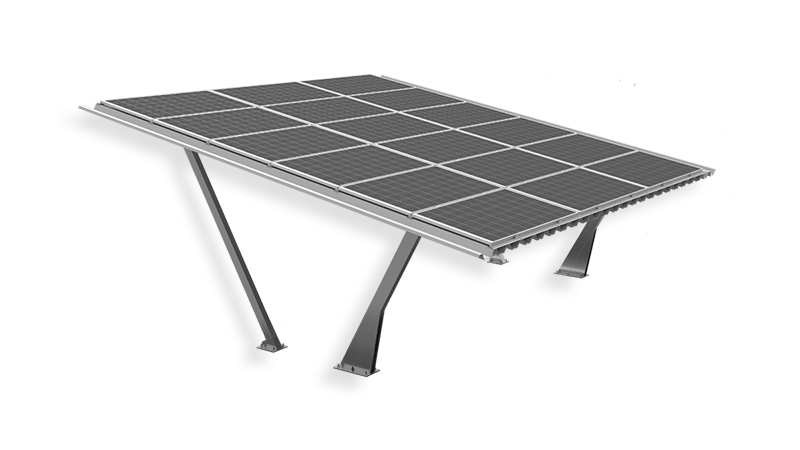

Bet on a proven business partner

Energy5 is a leading Polish manufacturer of mounting systems for photovoltaic modules, operating continuously since 2015. Our wide offer includes ground structures, roof structures, facade systems and AUTOBOX carports. Want to know the details? Contact technical and commercial advisors!